Maintenance Guide for Farming Equipment in the Autumn and Winter Seasons

Return to ListMaintenance and Care of Fans

Regular maintenance can extend the service life of the fan and prevent malfunctions. It is necessary to conduct regular inspections, adjustments, and maintenance on the frame, blades, bearings, all fixing screws, locking pins, and safety spacing.

1. Regularly keep the surface of the fan clean: There should be no debris at the inlet and outlet. Regularly remove dust and other impurities from the fan. Clean the dirt on the blades in time and clean the fan. Protect the motor and the bearing housing. Do not directly rinse the motor and the bearing housing with water. When the fan is stored outdoors, there should be protective measures. It must not be stored in overly humid, rainy, or exposed areas.

2. Regularly check the tension and wear condition of the belt: Check regularly whether the belt is loose and adjust the tensioning wheel; if the tension cannot be achieved or the wear is severe, replace it with a new belt of the same model.

4. Motor maintenance and servicing: Before using a motor that has been idle for more than three months, conduct a safety performance check to ensure that the mechanical parts of the motor are in good condition.

5. Blinds operate normally: If the blinds cannot be opened or closed properly, or if there are abnormal noises during operation, stop the machine immediately and report for repair.

6. Regular inspections should be conducted to check whether all the fixed components are loose. Once any looseness is detected, immediate tightening measures should be taken.

Maintenance and Care of the Wet Fan

1.It is necessary to promptly remove the spider webs and other debris from the wet curtain paper. Protective nets can be installed to prevent mice from damaging the wet curtain paper.

2. Check if the pump is operating abnormally and if it is overheating. Clean the filter device.

3. If water is leaking out of the wet curtain paper, simply adjust the position of the wet curtain paper or change the water flow volume.

4. Replace the water for the wet cooling system: Once a week. Pay attention to the maintenance of the wet cooling system to prevent the growth of algae.

Electronic control system

1. Check in time for any burnt smell or blackening phenomenon in the electrical cabinet to ensure fire safety during electricity usage;

2. Check in time whether any components of the electrical cabinet are abnormally hot;

3. Check in time whether the data of each instrument is abnormal (such as the temperature displayed by the environmental control unit, and whether the operating level of the environmental control unit is consistent with the actual situation);

Manure cleaning system

1.Check in a timely manner whether the manure scraping process is feasible, that is, whether it can effectively clean up the pig manure and automatically retreat due to the operation of the limit switch.

2. Regularly check whether the electrical components and motors during the cleaning process are abnormally overheating.

3. Regularly check whether the steel wire rope has any signs of fraying or other indications of imminent breakage;

4. Regularly check whether the running manure scraping motor has any abnormal sounds or teeth disengagement issues;

5. Lubricate and maintain the bearings of the manure scraping motor, apply grease. Maintenance frequency: once every 3 months.

6. Lubricate and maintain the scraper motor reducer. Add gear oil. Maintenance frequency: once a year.

Feeding line system - Double-sided food trough

1.Regularly check whether the food boxes and welding components are loose or have fallen apart (welding components falling into the manure ditch and affecting manure scraping operations, etc.).

2. Regularly check whether the material regulating mechanism of the double-sided food box is functioning properly;

3. Clean the double-sided feeding box. This should be done once a month or after each batch of pigs.

Take proper measures to keep warm

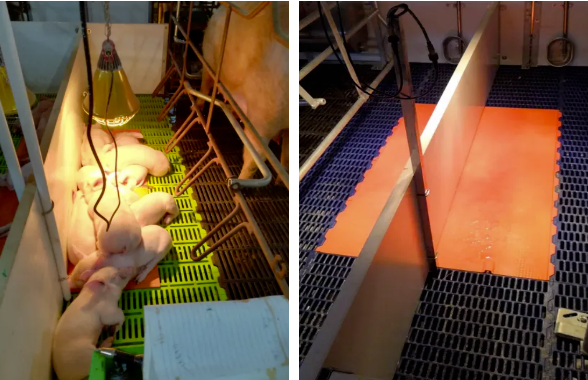

1. Inspect heating equipment: Ensure that heating pads, insulation lamps, and other heating devices are functioning properly.

2. Take measures to protect the equipment from cold and freezing. If the equipment is not in use during winter, make sure to drain all the water inside to prevent it from getting damaged due to freezing.

3. Repairing air leakage gaps: Conduct a thorough inspection and maintenance of the pigsty, including repairing damaged walls, ceilings, etc.

4. Lay down bedding or straw: This helps enhance the comfort of the pigs and insulates against the cold air from the ground. Also, hanging cotton or grass curtains at the door can prevent cold air from entering.

The above are some methods for maintaining the equipment in the pig farm. Proper maintenance of the equipment in the farm area helps ensure the safe and efficient operation of the housing facilities, and helps maintain the health of the pig herd and improve production efficiency. Therefore, pig farmers must pay attention to this and make preparations to ensure that their piglets can survive the winter smoothly!