Broiler Cage System Broiler Poultry Farming Equipment H Type Automatic System Battery Broiler Chicken Cage

Product Features

To meet different requirement,the manual bird-harvesting cage is designed .It is less cost and lower investment,it can be utilized in the available house.

Advantages of broiler cages

Our company is one of the earliest cage manufacture .According to Chinese characteristics of breeding big broiler,creatively improved broiler cage ,increase the height to suit the big broiler,to decrease the width of cage to get better ventilation.Many years of experience has proved our cage has god effect.From the narrow cage at first,Famou company has developed more than 10 type broiler cages,completely meet the various needs of all farmers.

Our cages are full processed by CNC machine,we can also design the individual cage as per the special requirement of customers to produce the personalized products.

In addition to our innovative design and manufacturing capabilities, we prioritize the welfare and productivity of the broilers raised in our cages. Our H-Type Automatic System is engineered to optimize space and enhance the living conditions for the chickens. Each cage is equipped with advanced feeding and watering systems that ensure consistent access to nutrition and hydration, promoting healthy growth and reducing stress among the birds. Furthermore, our cages are designed with easy maintenance in mind, allowing farmers to efficiently manage their flocks while minimizing labor costs. The durability of our materials ensures that the cages withstand the rigors of daily use, providing a long-term investment for poultry farmers. We understand that successful broiler farming requires not only quality equipment but also reliable support; thus, our team is committed to offering comprehensive training and ongoing assistance to our customers. By choosing our broiler cage system, farmers can expect improved production rates and enhanced overall flock health, ultimately leading to greater profitability in their operations. We are dedicated to fostering sustainable farming practices that benefit both the farmers and the animals, and we continually seek feedback to refine our products and services to better meet the evolving needs of the poultry industry.

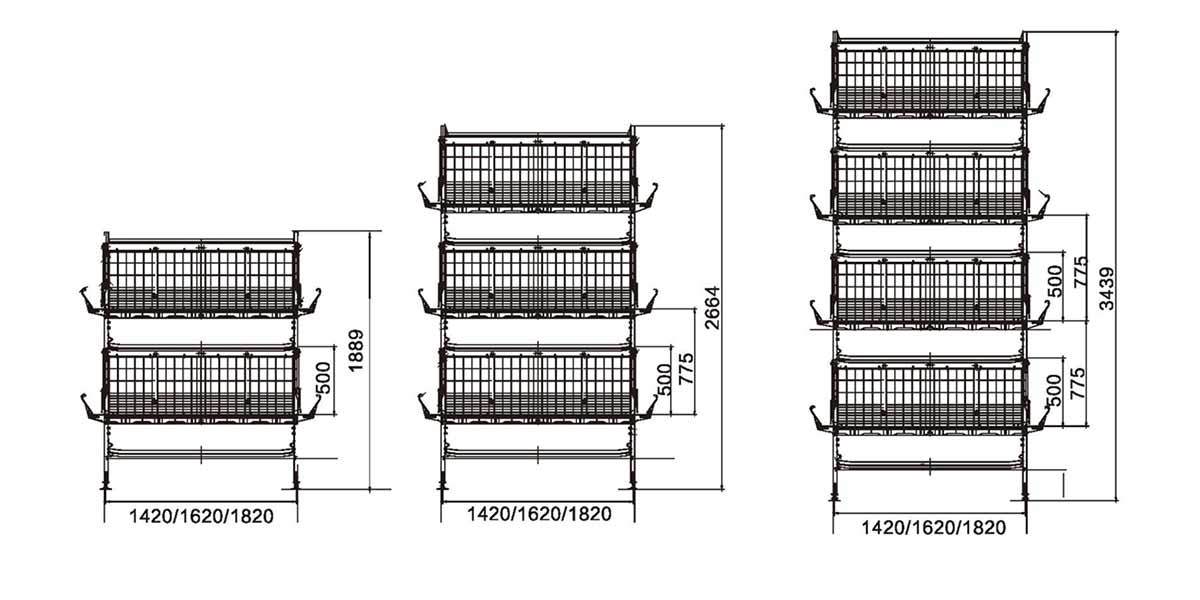

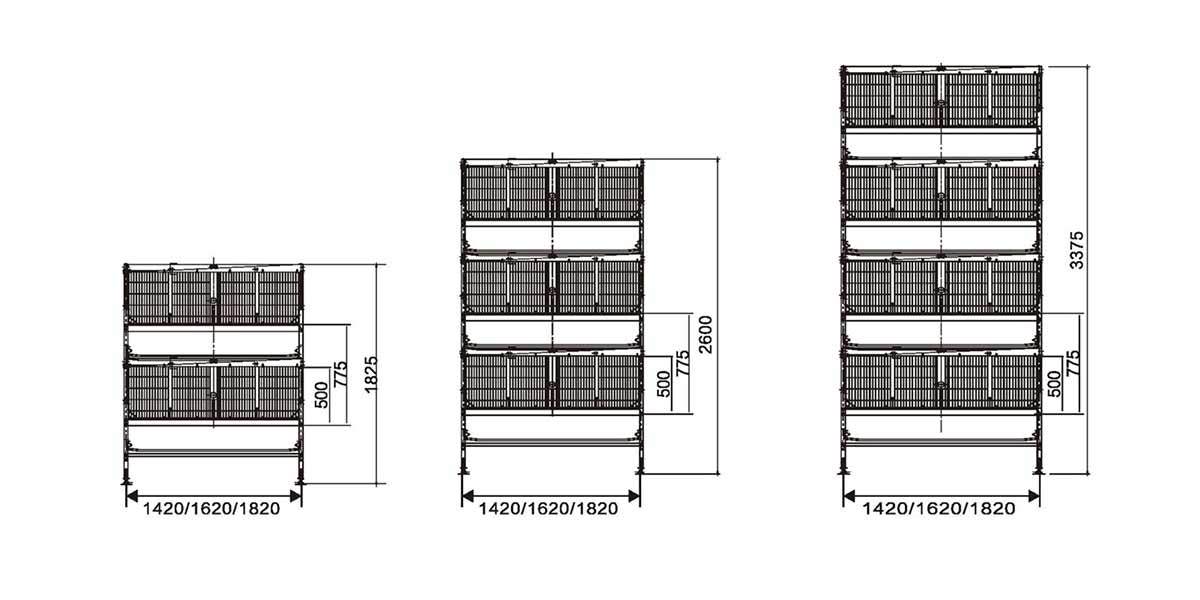

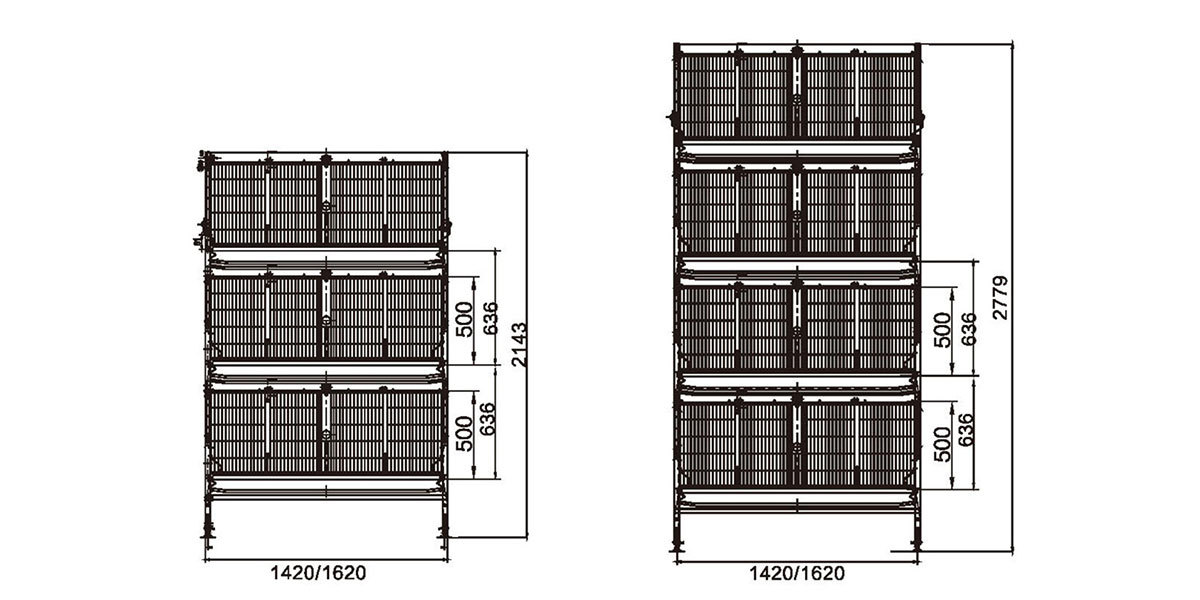

Size of Broiler Cage

1. Automatic Bird-harvesting (pan Feeding)

2. Automatic Bird-harvesting (trough Feeding)

3. Manual Bird-harvesting(pan Feeding)

To meet different requirement,the manual bird-harvesting cage is designed .It is less cost and lower investment,it can be utilized in the available house.

Quantity Of Broiler

Model |

Width(mm) |

Square Of Cage(mm²) |

Distance Of Two Legs(mm) |

LengthOf Unit(mm) |

Quantily of cell age |

|||

3kg |

2.5kg |

2kg |

1.5kg |

|||||

9LRC3126/4168 |

1420 |

1420×1500 |

1500 |

1500 |

35 |

42 |

53 |

70 |

9LRC3144/4192 |

1620 |

1620×1500 |

1500 |

1500 |

40 |

48 |

60 |

81 |

9LRC3162/4216 |

1820 |

1820×3000 |

1500 |

3000(Both groups are connected) |

90 |

108 |

136 |

182 |

9LRC3129/4172 |

1800 |

1800x2412 |

1206 |

2412(Both groups are connected) |

72 |

86 |

108 |

144 |

*only for reference

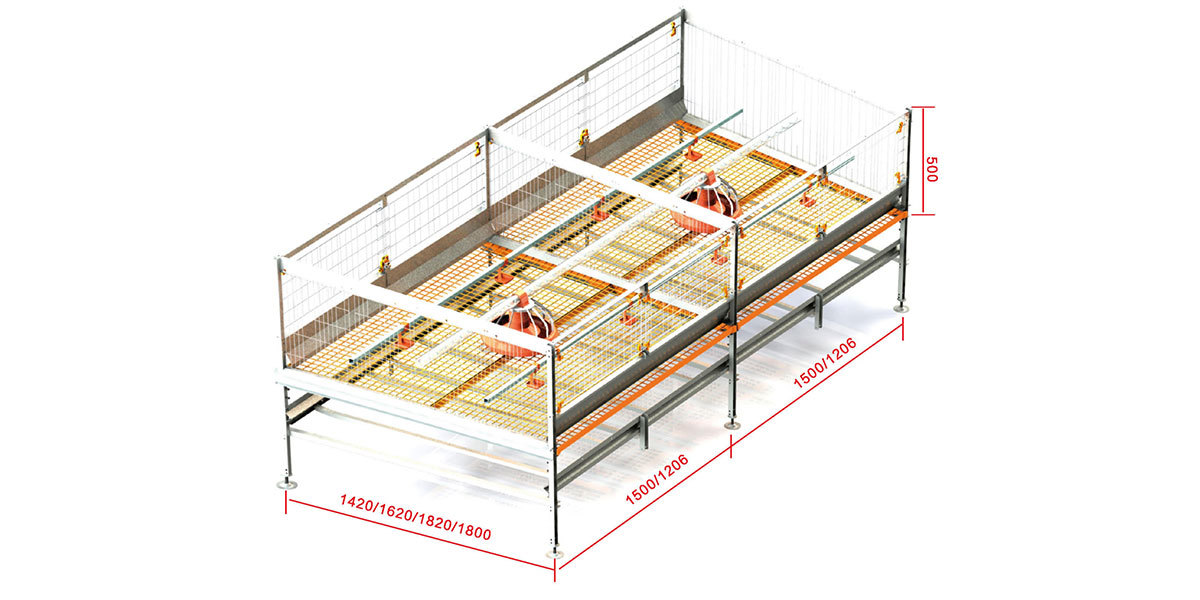

3D Of Broiler Cage

1 feed line with 1 feed pan and 2 drinking lines with 4 to 8 drinkers are set up in each cage.The reasonable configuration ensures that broilers can eat sufficient feeds and drink sufficient water.The height of feeding line and drinking lines can be freely adjusted according to the age of birds.

The length and height of each unit of cages are 1500mm and 500mm,and width is 1420mm/1620mm/1820mm for your options.This is more favorable for ventilation and provides more oxygen to birds while ensuring the firmness of cages.The experiences in many large scale companies have proven that our cages system can obtain more satisfactory feed conversion ratio and survival rate.

C-shape legs are formed of hot galvanized sheets for easy cleaning.

There are two types of broiler feeding modes,auger and trolley.With the auger feeding:the feeds are transported from silo into the hopper at the front of battery cages.Then the feeds are distributed quickly and uniformly via level feed lines into the pans in each tier.Every feed sensor could supply chicken enough food.

The height of pans can be adjusted according to the age of birds.

The trolley feeding mode:the feeds are transported by the auger to the trolley hopper at the front of each row.Then the feeds are uniformly distributed into the trough of each tier by a moving trolley.Meanwhile amount of feeds can be adjusted.

It is very important to keep the height of drinking line and feeding line.The special device is designed in Famou company,that is installed in middle of each row to ensure in a level as adjusting.

The design and material of floor are very important to broiler growing.Solid,flexible and hygienic floor can prevent breast hematoma,reduce diseases and the mortality of birds.Our floor use plastic bottom embedded with the galvanized tubes o increase strength.Proper square grids can ensure manure to leak out instead of be accumulated on the floor.

Our floor can be pulled out very easily,that is easy for cleaning up.As well as ensure birds to fall onto manure belts for automatic removal out in the final.

Broiler cage floor can be taken out freely.When the floor is drawn away,broilers drop onto the manure belt ,then conveyed onto the cross conveyor;via the cross conveyor belt,broilers are conveyed into the disc birds-catching machine outside the poultry house and then can be directly cased.